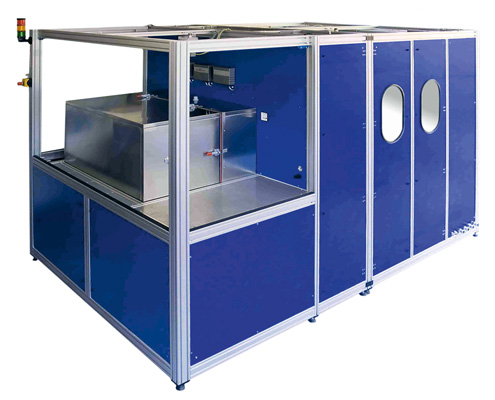

Fuel cell test bench with cold start function 80kW

Test bench for carrying out measurements on PEM stacks up to 80kW of electrical power under tempered ambient conditions. This system is optimised for the development and testing of automotive fuel cells with a focus on developing cold start strategies. A wide variety of cooling and cold start scenarios can be mapped with this system.

Temperature range

-30°C to +105°C (environment, gases and cooling water)

Special features

Temperature chamber in the test bench

Integrated recirculation circuit anode

Dynamic humidity, pressure and mass flow control

Max. current 900A / maximum voltage 600V / 80kWel

Fuel cell test bench with cold start function 150kW

With this testing system, measurements on PEM stacks up to 150kW electrical power are carried out under temperature-controlled ambient conditions. This test bench is designed for the development and testing of automotive fuel cells up to 150kW of electrical power under system-related conditions (e.g. integrated anode loops with purge valves, high-pressure connections for system metering valves and many other possibilities). Using the cold start function, a wide variety of cooling and cold start scenarios can be mapped.

Temperature range

-35°C to +105°C (environment, gases and cooling water)

Special features

Temperature chamber in the test bench

Recirculation / flow-through and high pressure operation on anode possible

Dynamic humidity, pressure and mass flow control

Max. current 900A / maximum voltage 800V / 150kWel

Short stack test bench PEM

Test bench 3.5kW

This test bench is used for measurements on PEM short stacks up to 900A with a switchable 0Volt option. The device is optimised for the development and testing of automotive fuel cells with a focus on developing anode-side operating strategies. Using the advanced safety technology, accelerated ageing effects can be simulated with the integrated Anode-Air Purge.

Temperature range

+20°C to +100°C (gases, dew points and cooling water)

Special features

Anode integrated with recirculation and flow-through operation

Anode air purge with advanced safety technology

Max. current 900A with 0Volt option

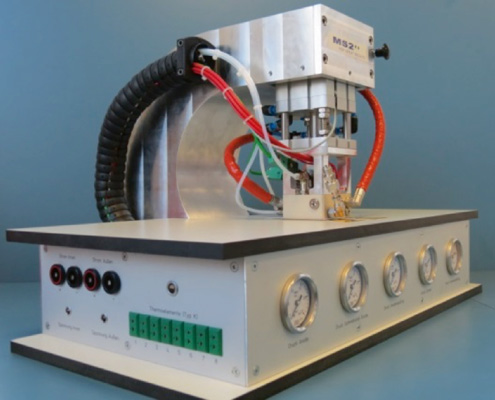

PEM stack test bench

14kW test bench

A testing system for carrying out measurements on PEM stacks up to 700A with up to 14kW electrical power. The test bench is designed for the development and testing of automotive fuel cells with a focus on developing cold start strategies and dynamic tests. A wide variety of cooling and cold start scenarios can be mapped with this system. The environment as well as all media can be cooled down to –30°C.

Temperature range

-30°C to +100°C (gases, cooling water and environment)

Special features

Dynamic humidity, pressure and mass-flow control

Dynamics below 1 sec (dew point 90)

Anode integrated with recirculation and flow-through operation

Single cell to short stack test bench PEM

Test bench 2kW

This test bench is used for measurements on PEM single cells and short stacks. Currents up to 500A with switchable 0Volt option. Other measurement techniques such as voltammetry or impedance spectroscopy can be integrated.

Temperature range

+20°C to +100°C (gases, dew points and cooling water)

Special features

Anode: integrated recirculation and through-flow operation

Endurance test system for MEA development

Single-cell / multi-cell PEM

Test bench 0.5kW

Test bench for measurements on PEM single cells as well as for examining components such as membranes, catalysts, seals, bipolar plates, … Other measurement techniques such as voltammetry or impedance spectroscopy are integrated.

Temperature range

+20°C to +100°C (gases, dew points and cooling water)

Special features

Endurance test system for MEA development

Air and pure oxygen operation

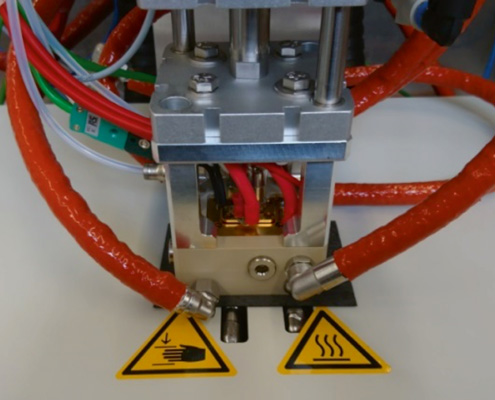

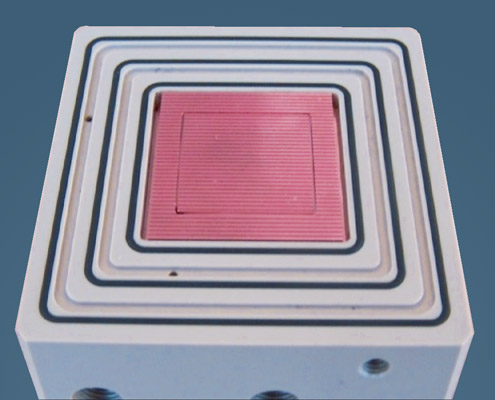

Measuring device for spatially-resolved material characterisation of PEM – MEA

Device for carrying out measurements and optimisations on PEM membranes and their components such as GDL. The non-destructive measurement of small areas of a membrane can be carried out freely on any size membrane / GDL at pressures up to 4bar and temperatures up to 90°C without the need for any additional provisions. Areas of application for this device are development, production and damage analysis.

Application

Equipment used for the material characterisation of small parts of a membrane electrode unit and its components under real process conditions

Special features

Defined boundaries (e.g. 25mm x 16mm)

Current density up to 10A/cm³

Water-cooled flow fields with a very low temperature gradient compared to the unit under test.

Integration of the measuring device into the test bench like “normal” fuel cells

Funding by ZIM and BMWi

Patent application